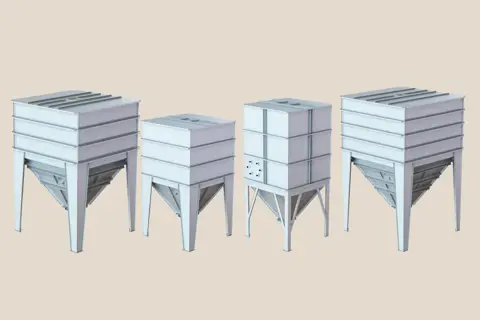

Gravity Mixing Silo

For mixed product that can demix by unloading.

Specifications

For use when you have a mixed product that can demix by unloading. This is a similar function as a pipe blending silo but with 12 different levels of blending. It dosn´t use any power for mixing. It can also be used for blending when you have external equipment for reloading this mixer.

BM gravity mixing silo is a further development of the BM Clean Silo but has extra built-in channels that control the flow. It is a highly functional product that in the same way as all the products by BM Silo can be shipped all over the world. The silo can be delivered as an indoor or outdoor mixing silo.

Applications for Gravity mixing silo

BM Gravity mixing Silo is the perfect choice for mixing and bulk storage of your dry materials such as wheat, barley, oats, meal feed or pellets.

Configurable

Our silos can be configured to meet your specific needs. They can be adjusted in design, made from stainless steel, or painted based on your preferences.

The Modular System

The modular system offers a multitude of combinations and easy adaptation which, combined with the square construction, ensures optimal space utilization. The silo is constructed according to the Eurocodes. The silo can fit through a regular doorway and be assembled on-site. Installation, service, and maintenance of worn parts can be done within confined spaces

The Mixing Process

The mixing process is done in the flow when unloading. This is to ensure no demixing of the material which can be used in various industries (plastic etc.). The homogenized material can contribute to a more streamlined production with more consistent results. Mixing the product while emptying the silo ensures a mixing witout any power consumption. The unique design of the Gravity Mixing Silo means also means that calibration between batches becomes needless resulting in a more efficient production process.

Hot-dip Galvanized

All panel sections on this silo are galvanized to give a long service life–as are all the silos manufactured at BM Silo. The smooth steel panels ensure good internal hygiene and optimum silo discharge.

The Bottom Cone

The bottom cone is constructed for high flow all the way to the outlet. The cone is specialized for the Gravity Mixing silo which has a higher flow than a regular Modular or Clean silo.

Compact Kit

Compact kit it is well known that the silos at BM Silo are delivered as kits that are stackable. This means that all our products can be delivered to any destination and can fit through a regular house door. Your production does not need to be set on pause during delivery and installation.

The Leg Length

The leg length the discharge height can be adjusted as required by adjusting the length of the legs. A specialization that is possible here as with all silos at BM Silo.

Standard Equipment

The Gravity Mixing Silo is supplied with a split steel cover with a square adaptor plate 415x415mm for a wide range of adaptors, which ensures easy connection to filling equipment in the center of the cover.

Optional Equipment

Optional equipment such as reinforced cover, Injection unit with tanker connection flange, cyclone, and piping, guardrails, level sensors, load cells with display, vibrators, and connecting pieces for augers and feed system inlets can be delivered.

Product Assortment

|

Measurements (mm) |

Height (m) |

Contents (m³) |

Load metre |

Indicative installation hours |

|---|---|---|---|---|

| 2125 x 2152 | 4,74 - 10,68 | 12,28 - 34,83 | 1,4 | 9,0 - 31,5 |

| 2711 x 2711 | 4,8 - 8,85 | 17,63 - 41,93 | 2,7 | 10,5 - 39 |

| 3147 x 3147 | 5,31 - 10,26 | 25,26 - 66,85 | 3,2 - 6,4 | 10,5 - 48 |